Basic Info.

Model NO.

diameter 6mm length 50mm

Tolerance of Diameter

-0.05~+0.05

Length

50mm

Tolerance of Length

-0.5~+0.5

Angle of Needle

53 Degree

Transport Package

25kg. Carton

Specification

YL10.2

Trademark

ZZUP

Origin

Zhuzhou, Hunan, China

HS Code

820900100

Production Capacity

10000000PCS/Month

Packaging & Delivery

Package Size

5.00cm * 5.00cm * 5.00cm

Package Gross Weight

0.500kg

Product Description

diameter 6mm length 50mm hardness from 90.5~94hra wc alloy steel tungsten carbide needle

Products description

Products description

1. Grade: YL10.2,YG10X,YG12X,YG15,YG20,YG10,YG8,YG8 etc.

2. diameter from 0.3mm~100mm,

3. length from 10mm~1000mm

4. tolerance for diameter (.-0.05~+0.05),tolerance for length (0~+0.2mm).

5. angles of tips are 30º,60º,90º

| Product Name | diameter 6mm length 50mm hardness from 90.5~94hra wc alloy steel tungsten carbide needle |

| Material | tungsten carbide |

| Color | grey |

| Standard | DIN GB ISO JIS BA ANSI |

| Grade | YL10.2,YG10X,YG12X,YG15,YG20,YG10,YG8,YG8 etc |

| Brade | ZZUP |

| Grain size | 0.6um |

| Used | for milling 45HRC,50HRC,60HRA metals |

Drawing and sizes

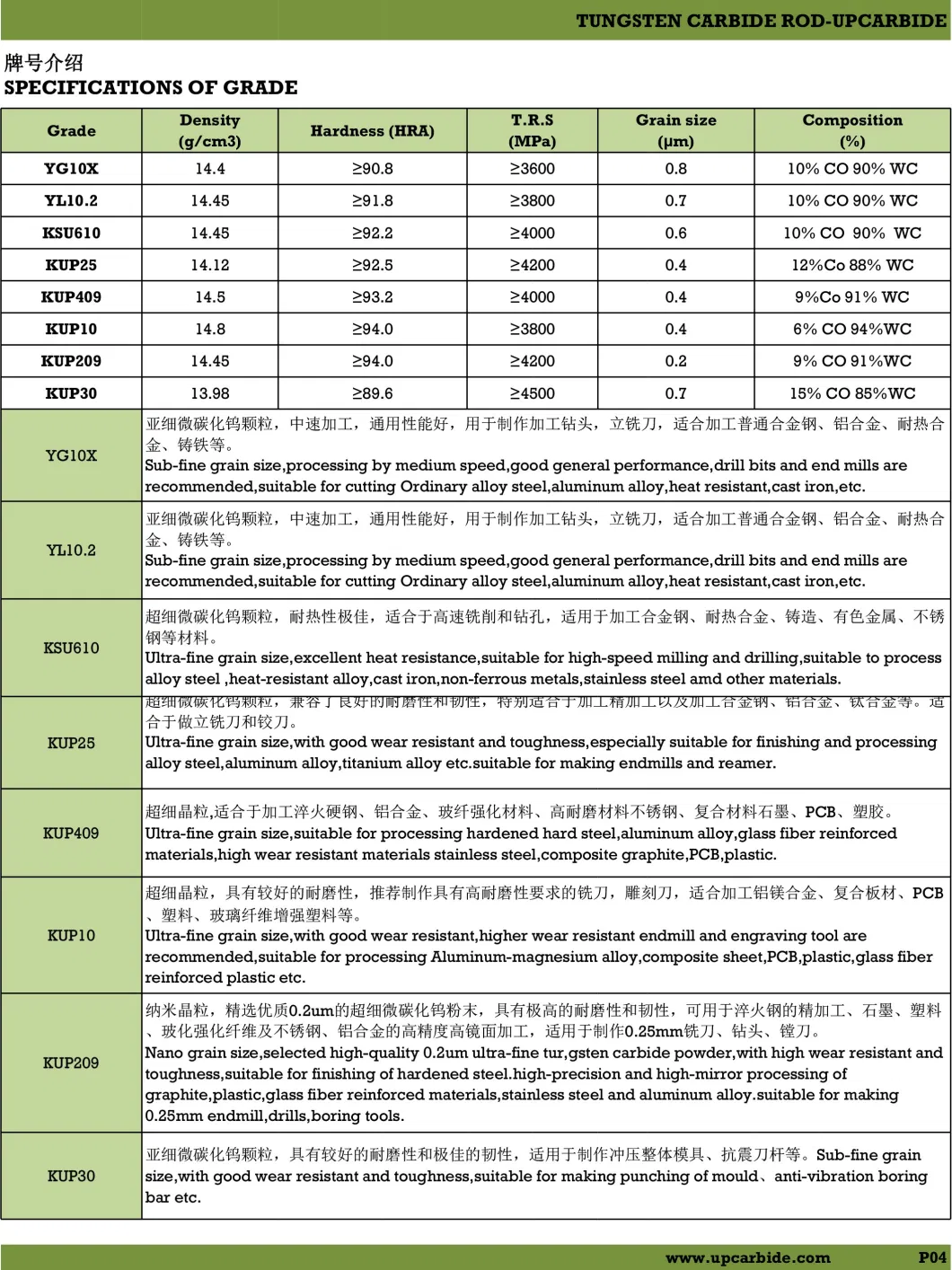

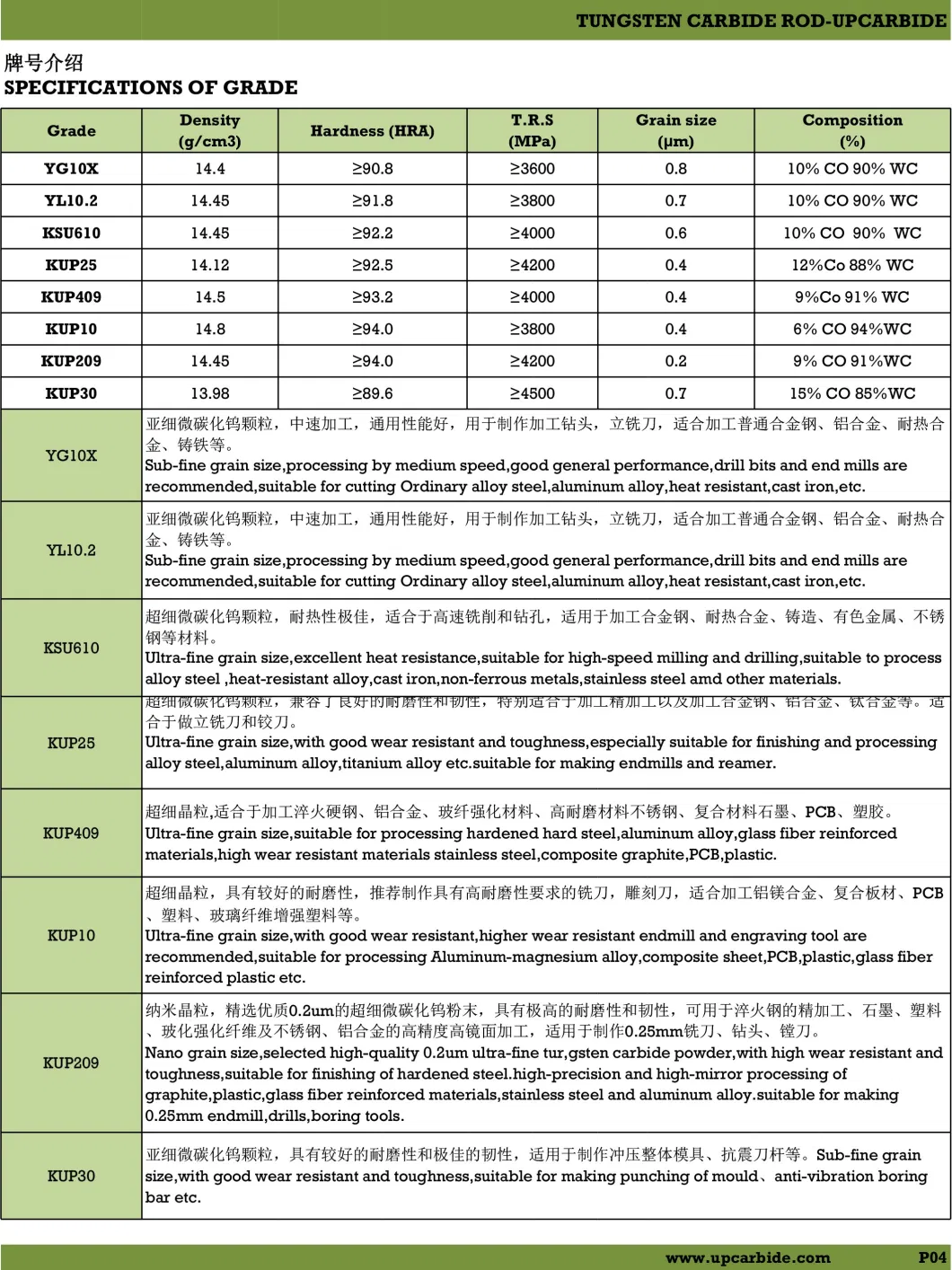

Grade specification

Packing details

Shipping ways

Production process

Tungsten carbide thimble /needle /grinding point rod introduction:

Tungsten carbide thimble is made of high-quality tungsten carbide material by precision equipment grinding, polishing made of thimble, commonly known as: thimble, support needle, double thimble, flat thimble, insert needle, PIN needle. Because it uses high-quality tungsten carbide material with high hardness 92.0hRA and 4000MPa bending strength, it has high wear resistance and excellent corrosion resistance. It is usually used in plastic moulds. It plays a role in separating plastic products from the moulds, and can also be used through thin and long pinholes. It is often used for lathes and grinding machines to support the workpiece and make the workpiece revolve around it. It is also suitable for making tungsten carbide electrode rod in photoelectric industry. The tip Angle is controlled between 10° and 15°. It is mainly used for automatic solid crystal machine equipment, supporting (top up) auxiliary vacuum adsorption system.

Tungsten steel thimble production process:

1.Ingredients (according to the requirements of applicable selection of tungsten carbide powder + cobalt powder) to the mix - crushing - drying, sieving after forming agent and dry again to sieving mixture system, the mixed system, pressing - molding - Germany import vacuum suit low sintering sintering furnace - after sintered blank - test (nondestructive ultrasonic flaw detection) - blank dimensions accuracy test - cutting molding to coarse grinding, fine grinding Polishing → inspection → packaging → storage.

Characteristics of tungsten steel thimble:

1Due to the addition of tantalum carbide TaC with excellent wear resistance and TiC with excellent heat and wear resistance in the alloy composition, it has high wear resistance and its service life is more than 3 times that of SKH51 high speed steel and 65Mn manganese steel.

2.Precise size, high machining accuracy, polishing finish Ra≥0.012 mirror effect.

3.Tungsten carbide thimble has excellent corrosion resistance without rust, can work in acid and alkaline environment, can greatly reduce maintenance cost and maintenance time.